The Importance of FR Ratings in Jackets and How to Choose the Right One for Your Needs

When it comes to safety at work, especially in industries where there's a risk of fire or electrical hazards, wearing the right clothing is crucial. This is where Flame Resistant (FR) clothing comes in, providing essential protection.

But it's not just about wearing any FR clothing; understanding and choosing the right FR ratings for your specific needs is key. Let's dive into what FR ratings are, how they are determined, and why they are so important.

What are FR Ratings?

FR Ratings refer to the level of protection provided by flame-resistant clothing against fire hazards. These ratings are crucial in ensuring that workers are adequately protected in environments where they might be exposed to flames, electric arcs, or flash fires.

Table: Different FR Ratings and Their Meanings

To help you understand the different FR ratings, here’s a simplified breakdown:

-

ATPV (Arc Thermal Performance Value): This measures the level of protection a fabric provides from an electric arc. It's expressed in calories per square centimeter (cal/cm²), indicating how much energy the fabric can block before causing a second-degree burn.

source: Arcwear Testing -

EBT (Energy Breakopen Threshold): Similar to ATPV, but used when fabric breaks open before reaching the ATPV level. It also measures the energy level at which there is a 50% probability of breakopen.

source: Arcwear Testing -

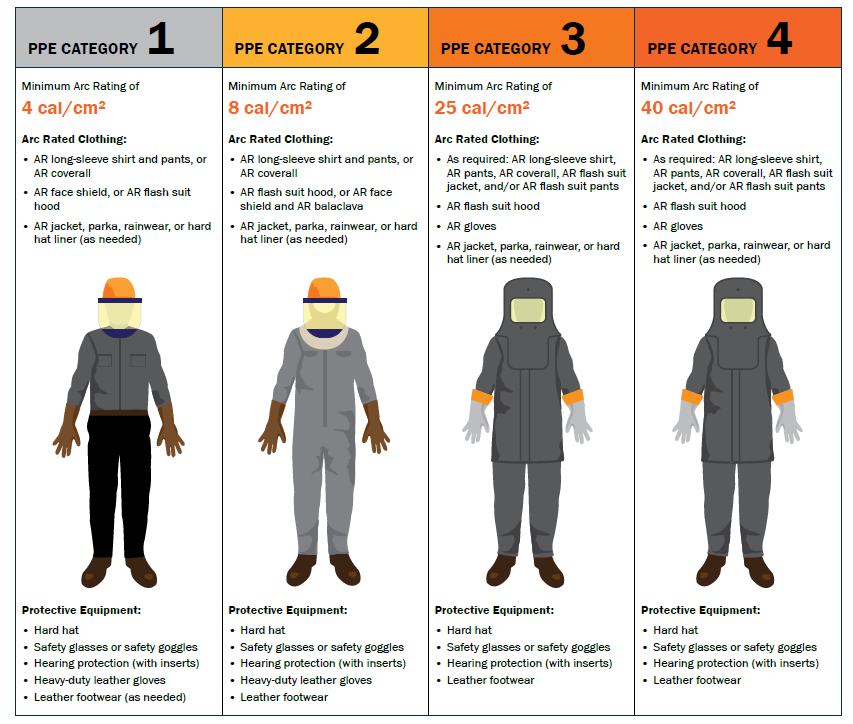

PPE Categories: These categories, as defined by NFPA 70E standards, range from CAT 1 to CAT 4, with each category indicating a range of arc ratings. For example, CAT 1 corresponds to an ATPV of at least 4 cal/cm².

How are FR Ratings Determined?

FR ratings are determined through rigorous testing methods. The most common test for FR fabrics is the ASTM F1959, which determines the Arc Thermal Performance Value (ATPV) or Energy Breakopen Threshold (EBT). These tests expose the fabric to an electric arc and measure how well it resists heat and fire. The higher the ATPV or EBT rating, the more protective the fabric is.

PPE Categories - NFPA 70E standards

NFPA 70E, a standard for electrical safety in the workplace, establishes Personal Protective Equipment (PPE) categories for protection against arc flash hazards. These categories are crucial for ensuring the safety of workers exposed to electrical hazards.

NFPA 70E (2018) outlines four PPE categories, each with a minimum Arc Rating value indicating the level of protection required based on the severity of the potential electrical hazard.

PPE Category 1:

-

This is the lowest level of Arc Rated PPE.

-

Requires a single layer of arc-rated PPE.

-

Minimum Arc Rating: 4 cal/cm².

-

Includes long-sleeve shirt (or jacket) and pants or arc-rated coverall.

-

Additional PPE: Face shield or arc flash suit hood, heavy-duty leather gloves, hard hat, eye protection, hearing protection, and as-needed leather footwear.

PPE Category 2:

-

Can also be met with a single layer of Arc Rated PPE.

-

Minimum Arc Rating: 8 cal/cm².

-

Required clothing includes arc rated long-sleeve shirt and pants or arc-rated coverall.

-

Additional PPE: Arc flash suit hood or arc-rated face shield, sock hood/balaclava, heavy-duty leather gloves, hard hat, eye protection, hearing protection, and as-needed leather footwear.

PPE Category 3:

-

Requires multiple layers of PPE.

-

Minimum Arc Rating: 25 cal/cm².

-

Required clothing includes arc arc-rated flash suit jacket, AR pants, or coverall.

-

Additional PPE: Arc flash suit hood, rubber insulating gloves & leather protectors or arc-rated gloves, hard hat, eye protection, hearing protection, and leather footwear.

PPE Category 4:

-

Highest level of protection.

-

Minimum Arc Rating: 40 cal/cm².

-

Required clothing includes arc arc-rated flash suit jacket, AR pants, or coverall.

-

Additional PPE: Arc flash suit hood, rubber insulating gloves & leather protectors or arc-rated gloves, hard hat, eye protection, hearing protection, and leather footwear.

The Importance of Proper FR Rating

Choosing the right FR rating is critical for ensuring safety in hazardous work environments. Wearing clothing with an appropriate FR rating can significantly reduce the risk of severe burn injuries in the event of an arc flash, flash fire, or electric arc incident.

It's not just about meeting legal and safety standards set by organizations like the National Fire Protection Association (NFPA) and the National Electrical Safety Code (NESC); it's about ensuring that workers are properly protected from recognized hazards.

For instance, in industries like electric power generation, chemical manufacturing, or construction, where workers are exposed to potential arc flashes and flash fires, FR clothing can be the difference between minor injuries and life-threatening burns. Therefore, it's crucial to select FR garments, such as FR coveralls, jackets, or shirts, that are not only flame resistant but also have the appropriate arc rating and comply with relevant safety standards.

Legal Standards and Regulations for FR-Rated Jackets According to NFPA

When it comes to FR-rated jackets, compliance with legal standards and regulations is paramount for ensuring safety. The key standards set by the National Fire Protection Association (NFPA) primarily involve the Arc Rating, a critical measure for the protective qualities of FR clothing.

-

NFPA 70E: This standard specifies the requirements for Arc Rated Clothing to protect against electrical hazards, like arc flashes. It is especially relevant in electrical utilities where an arc flash explosion could occur.

-

NFPA 2112: Focused on protective clothing for industrial personnel against flash fires, it sets requirements for Flame Resistant Fabrics and garments to resist ignition and self-extinguish.

-

OSHA Regulations: While OSHA does not have specific standards for FR clothing, it refers to NFPA standards under the General Duty Clause. OSHA requires employers to protect workers from fire-related hazards and serious physical harm in the workplace.

Factors to Consider When Choosing an FR Jacket

1. Material and Construction

Table: Types of FR Materials and Their Properties

-

Inherently FR Fabrics: Made from fibers naturally resistant to flames, like Nomex®. They offer excellent thermal insulation and don't melt.

-

Treated FR Fabrics: Cotton or blend materials treated with fire retardant chemicals. They are cost-effective but may lose some flame-resistant properties over time.

-

Blended FR Fabrics: Combine the best qualities of inherent and treated fabrics for durability and flame resistance.

2. Industry and Environmental Considerations

It's crucial to consider the specific industry and environmental conditions where the FR jacket will be used. For instance, in environments where arc flash explosions or electric arc incidents are probable, Arc Rated Clothing with a higher Arc Flash Rating is essential.

Industries like chemical processing or electrical utilities may require FR garments with specific properties, like resistance to certain chemicals or enhanced thermal insulation.

3. Comfort and Fit

Comfort and fit are critical in selecting FR clothing. Comfortable FR clothing, like a well-fitted FR shirt, encourages compliance among employees, ensuring they are properly protected.

Good fit contributes to mobility, reducing the risk of accidents and enhancing the ability to perform tasks efficiently. Comfort also mitigates heat stress, a significant factor in environments with high temperatures or active work.

Conclusion

Selecting the right FR (Flame Resistant) jacket is a crucial decision for ensuring safety in hazardous work environments. Understanding FR ratings, such as ATPV and EBT, and complying with standards like NFPA 70E and NFPA 2112, is essential for protection against fire hazards and electrical dangers.

When choosing an FR jacket, factors like material and construction, industry and environmental considerations, and comfort and fit must be taken into account.

Ultimately, investing in the right FR clothing not only meets legal and safety requirements but significantly reduces the risk of severe injuries, making it a vital aspect of workplace safety.